Product Descriptio

| Pos. |

Part No |

Qty |

Parts name |

Comments |

| 1 |

5I-9287 |

[1] |

SHAFT-PINION |

|

| 2 |

5I-9288 |

[1] |

CAGE |

|

| 3 |

095-1563 |

[1] |

SEAL-O-RING |

|

| 4 |

5I-9289 |

[1] |

BEARING AS |

|

| 5 |

123-1764 |

[1] |

HOUSING |

|

| 6 |

5I-9291 |

[1] |

SEAL-LIP TYPE |

|

| 7 |

5I-9292 |

[1] |

BEARING AS |

|

| 8 |

5I-9293 |

[2] |

SPACER |

|

| 9 |

5I-9294 |

[2] |

PIN |

|

| 10 |

5I-9295 |

[1] |

GEAR-SUN (17-TEETH) |

|

| 11 |

5I-9296 |

[1] |

GEAR-RING (58-TEETH) |

|

| 12 |

5I-9297 |

[1] |

GEAR-SUN (15-TEETH) |

|

| 13 |

5I-9298 |

[1] |

RING |

|

| 14 |

5I-9299 |

[1] |

SEAL-LIP TYPE |

|

| 15 |

5I-9300 |

[1] |

BEARING-ROLLER |

|

| 16 |

143-8089 |

[1] |

HOUSING |

|

| 17 |

5I-9302 |

[1] |

PLATE |

|

| 18 |

5I-9303 |

[1] |

PLATE |

|

| 19 |

5I-9304 |

[1] |

SPRING |

|

| 20 |

5F-3106 |

[1] |

SEAL-O-RING |

|

| 21 |

2H-3935 |

[1] |

SEAL-O-RING |

|

| 22 |

127-0012 |

[1] |

SEAL-O-RING |

|

| 23 |

114-0606 |

[1] |

PLATE |

|

| 24 |

5I-9308 |

[4] |

BUSHING |

|

| 25 |

5I-9309 |

[4] |

RING |

|

| 26 |

099-0371 |

[2] |

PLUG |

|

| 27 |

095-1579 |

[2] |

SEAL-O-RING |

|

| 28 |

5I-9310 |

[4] |

PLATE |

|

| 29 |

5I-9311 |

[1] |

RING |

|

| 30 |

5I-9312 |

[1] |

BEARING |

|

| 31 |

114-0607 |

[2] |

PISTON |

|

| 32 |

114-0611 |

[2] |

RING |

|

| 33 |

116-3410 |

[1] |

COVER |

|

| 34 |

5I-9315 |

[16] |

SPRING |

|

| 35 |

5I-9316 |

[1] |

PISTON-BRAKE |

|

| 36 |

5I-9317 |

[2] |

PLATE |

|

| 37 |

5I-9318 |

[2] |

PLATE-FRICTION |

|

| 38 |

5I-9320 |

[1] |

BARREL AS |

|

| 39 |

110-7182 |

[1] |

PISTON AS |

|

| 40 |

095-0966 |

[1] |

PLUG |

|

| 41 |

095-9232 M |

[6] |

BOLT-SOCKET HEAD (M12X1.75X95-MM) |

|

| 42 |

5I-9322 |

[1] |

CARRIER AS |

|

| 43 |

5I-9329 |

[1] |

CARRIER AS |

|

| |

5I-9323 |

[3] |

GEAR-PLANETARY |

|

| |

5I-9324 |

[3] |

BUSHING |

|

| |

5I-9325 |

[3] |

WASHER |

|

| |

5I-9326 |

[3] |

SHAFT-PLANETARY |

|

| |

5I-9328 |

[1] |

CARRIER-PLANETARY |

|

| |

099-8111 |

[3] |

PIN-SPRING |

|

| 44 |

096-5932 |

[2] |

PLUG |

|

| 45 |

096-5934 |

[2] |

SPRING |

|

| 46 |

096-5933 |

[2] |

VALVE-CHECK (MAKEUP) |

|

| 47 |

095-1587 |

[2] |

SEAL-O-RING |

|

| 48 |

095-1786 |

[2] |

RING-BACKUP |

|

| 49 |

5I-9331 |

[2] |

VALVE AS |

|

| 50 |

099-0329 |

[1] |

PIN |

|

| 51 |

095-1789 |

[2] |

RING |

|

| 52 |

095-1594 |

[4] |

SEAL-O-RING |

|

| 53 |

137-9279 |

[2] |

VALVE GP-RELIEF |

|

| 54 |

8T-3957 M |

[4] |

BOLT-SOCKET HEAD (M12X1.75X30-MM) |

|

| 55 |

9S-4191 |

[1] |

PLUG |

|

| 56 |

3J-1907 |

[1] |

SEAL-O-RING |

|

| 57 |

2D-6392 |

[3] |

SEAL-O-RING |

|

| 58 |

7I-2883 |

[1] |

VALVE AS |

|

| 59 |

095-0968 |

[2] |

PLUG |

|

| |

M |

|

METRIC PART |

|

Maintenance

The swing part of a Carter excavator is one of the important components, and it needs regular maintenance to ensure its normal operation and extend its service life. Here are some common steps for maintaining the swing of a Carter excavator:

Cleaning the swing part: Use a high-pressure water gun or detergent to clean the swing part to remove accumulated dirt, dust and other debris. Make sure it is cleaned thoroughly and be careful not to spray water directly into the electrical and hydraulic components.

Lubrie the swing part: Check and lubrie the lubriion points of the swing part, including the swing bearing, gears and connecting parts. Use appropriate lubricants and lubrie according to the manufacturer's recommendations.

Inspect the swing bearing: Check the wear and looseness of the swing bearing. Make sure there is no abnormal noise or excessive looseness of the swing bearing. If any abnormality is found, it should be repaired or replaced in time.

Inspect the gears and transmission parts: Check the wear of the gears, chains and transmission parts of the swing part. Clean, lubrie or replace if necessary.

Inspect the electrical system: Check the electrical system of the swing part, including the connecting lines, switches and sensors. Make sure the electrical system is working properly and there are no damaged or loose parts.

Check the hydraulic system: Check the hydraulic system of the swing part, including the quality and level of the hydraulic oil. If necessary, replace the hydraulic oil and clean the hydraulic filter.

Check the safety devices: Make sure that the safety devices of the swing part, such as warning lights, sound alarms and limiters, are working properly.

Please note that the above steps are only general guidelines, and the specific maintenance procedures and requirements may vary depending on the model, year and manufacturer. Therefore, it is recommended to refer to the user manual of the excavator or consult a professional technician to ensure the correct swing maintenance procedures. In addition, regular maintenance and inspections are essential to keep the excavator in good condition and safe operation.

Packing

Shipping methods

BY EXPRESS, AIR, SEA

About Xinfeng Machinery (XF) parts:

Xinfeng Machinery Parts Company was established in 1998. It is a professional team composed of high-quality technical personnel integrating production, maintenance, sales, and service. It is committed to providing customers with high-quality and efficient services. It is headquartered in Guangzhou, China.

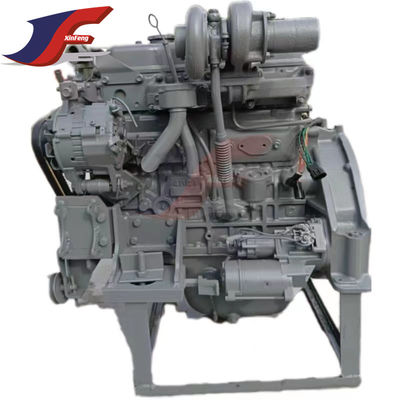

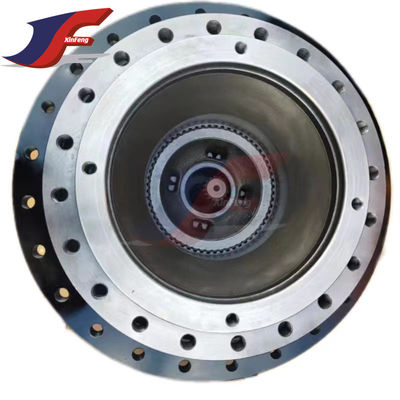

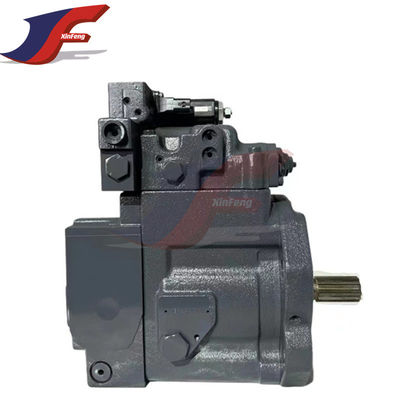

We have been engaged in the excavator industry for 25 years. We sell original used parts, rebuilt parts,original new parts, and OEM new parts for many types.We can provide many types for you to choose from. We can provide a quality-trusted full range of hydraulic pumps, travel motors, final drives, main control valves, swing motors, and engines for KOMATSU, , HITACHI, JOHN DEERE, VOLVO, CASE JCB, KOBELCO, NEW HOLLAND, SUMITOMO, KATO, BOB, DOOSAN, and HYUNDAI.

We provide a customer satisfaction guarantee on all our products. We have invested in providing only the highest-quality replacement parts to our customers. Develop a more broad business space together based on long-term, friendly, mutually beneficial, and win-win business relations.

FAQ

1. How to quickly and accurately buy products what lneeded?

A: Provide the original parts number to us to check.

2. How long have you been in the excavator

A: We are engaged in excavator parts since 1998

3. lfI don't know the part number,what shouldI do?

A: Please send us size and pictures of old products.

4. What is the warranty of the products?

A: The warranty is 6/12 Months based on the specific product.

5. How long is your delivery time?

A: The normal delivery time is 3-5 days for stock sproductsafter getting payment. lf not in stock, we will inform you thetime requlred.

6. Which shipping term you can supply?

A: By sea,air or by express ( DHL,Fedex,TNT,UPSEMS)

7. What is your MOQ?

A: Small order and sample order are acceptable

8. Do you have any After-Sales service?

A: Yes!Our

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!