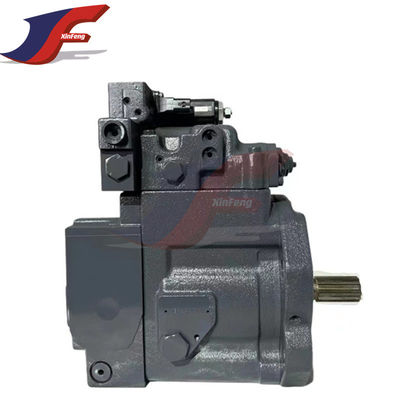

ZX120 ZX130 Hydraulic Main Pump Part HPK055 9192497 Piston Pump Repair Kit

Product Descriptio

| Pos. |

Part No |

Qty |

Parts name |

| |

+++++++ |

[1] |

PUMP;UNIT |

| 1 |

1026892 |

[1] |

CASING;FRONT |

| 2 |

2038178 |

[1] |

SHAFT;DRIVE |

| 3 |

4355286 |

[1] |

RACE;INNER |

| 4 |

4229543 |

[1] |

RING;RETAINING |

| 6 |

4280841 |

[1] |

BRG.;ROL. |

| 7 |

991342 |

[2] |

RING;RETAINING |

| 8 |

4343074 |

[4] |

O-RING |

| 9 |

4198956 |

[4] |

PIN |

| 10 |

2042069 |

[2] |

PLATE |

| 11 |

M340613 |

[8] |

BOLT;SOCKET |

| 12 |

1025666 |

[1] |

PLATE;SWASH |

| 13 |

4382272 |

[2] |

PLATE |

| 13 |

4407464 |

[2] |

PLATE |

| 14 |

9134109 |

[6] |

PLUG |

| 14A. |

4506408 |

[1] |

O-RING |

| 17 |

2042059 |

[2] |

ROTOR |

| 18 |

4289874 |

[2] |

SPRING;DISC |

| 19 |

3065991 |

[2] |

BUSHING |

| 20 |

3065989 |

[2] |

RETAINER |

| 22 |

8071391 |

[18] |

PISTON |

| 24 |

4410166 |

[2] |

O-RING |

| 26 |

1025540 |

[1] |

CASING;REAR |

| 27 |

2038174 |

[1] |

SHAFT;DRIVE |

| 28 |

1025667 |

[1] |

PLATE;SWASH |

| 29 |

4355279 |

[1] |

BRG.;ROL. |

| 30 |

927488 |

[2] |

RING;RETAINING |

| 34 |

3076 |

[1] |

CASING;PUMP |

| 35 |

4355272 |

[1] |

BRG.;NEEDLE |

| 36 |

4355277 |

[1] |

BRG.;NEEDLE |

| 37 |

4271350 |

[4] |

PIN;KNOCK |

| 38 |

2044792 |

[1] |

PLATE;VALVE |

| 39 |

2044793 |

[1] |

PLATE;VALVE |

| 42 |

4428917 |

[6] |

PISTON;SERVO |

| 43 |

4397537 |

[6] |

SPRING;COMPRES. |

| 45 |

4409640 |

[2] |

PIN;KNOCK |

| 47 |

4432356 |

[2] |

PIN |

| 48 |

4436322 |

[4] |

RING;BACK-UP |

| 49 |

4180349 |

[4] |

O-RING |

| 51 |

4200227 |

[2] |

PIN |

| 52 |

3081504 |

[2] |

LINK |

| 53 |

4397509 |

[2] |

PIN |

| 54 |

4404102 |

[2] |

PIN |

| 55 |

4144013 |

[2] |

PIN;SPRING |

| 56 |

4116299 |

[2] |

PIN;SPRING |

| 58 |

M341240 |

[12] |

BOLT;SOCKET |

| 59 |

495841 |

[12] |

WASHER;SPRING |

| 61 |

4427347 |

[3] |

PLUG |

| 62 |

9134111 |

[2] |

PLUG |

| 62A. |

4509180 |

[1] |

O-RING |

| 63 |

9134110 |

[2] |

PLUG |

| 63A. |

957366 |

[1] |

O-RING |

| 66 |

4436271 |

[2] |

SENSOR;PRES. |

| 66A. |

4365826 |

[1] |

O-RING |

| 67 |

4265372 |

[1] |

SENSOR;REVOL. |

| 68 |

4306888 |

[1] |

O-RING |

| 69 |

A590106 |

[1] |

WASHER;PLANE |

| 70 |

M340616 |

[1] |

BOLT;SOCKET |

| 71 |

4252767 |

[1] |

BRACKET |

| 72 |

M340613 |

[1] |

BOLT;SOCKET |

| 73 |

4169516 |

[1] |

WASHER;SPRING |

| 76 |

4515041 |

[4] |

PIN;SPRING |

| 77 |

4348665 |

[2] |

O-RING |

| 78 |

4180349 |

[10] |

O-RING |

| 79 |

4343074 |

[4] |

O-RING |

| 82 |

4320490 |

[1] |

SEAL;OIL |

| 83 |

930451 |

[1] |

RING;RETAINING |

| 100 |

4463047 |

[1] |

KIT;SEAL |

Maintenance method

1. Replace seals regularly

The service life of seals is generally one and a half to two years, and they must be replaced in time to ensure the tightness of the seal.

2. Avoid impact pressure damaging components

Impact pressure in the hydraulic pressure should be avoided during operation, as impact pressure will damage components. Each pressure valve and each flow valve must be reasonably adjusted strictly in accordance with the design requirements. After adjustment, the adjusting screws must be tightened securely.

3. Always pay attention to the temperature of the hydraulic station

The working temperature of the hydraulic system oil must not exceed 70°C, and should generally be controlled within the range of 35~60°C. If it exceeds the specified range, the cause should be checked and eliminated.

4. Maintain the quality of hydraulic oil

Select hydraulic oil according to the brand number specified in the instruction manual. The oil must be filtered before refueling. At the same time, the oil quality must be sampled and tested regularly. If the oil quality is found to be unsuitable for use, it must be replaced. Generally, it must be replaced every six months or every 2,000 working hours.

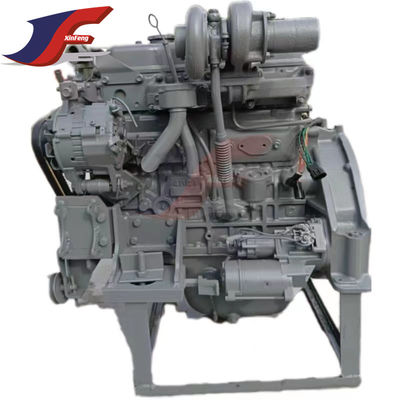

Theory

1. The hydraulic pump is the power component of the hydraulic system. It is driven by an engine or electric motor, sucks oil from the hydraulic oil tank to form pressure oil, and then discharges it and delivers it to the actuator. Hydraulic pumps are divided into gear pumps, plunger pumps, vane pumps and screw pumps according to their structures.

2. Working principle of hydraulic pump: The pump is an energy conversion device that converts the rotating mechanical energy of the motor into hydraulic energy for output. Hydraulic pumps operate on the principle of changing seal volume and are therefore often called positive displacement hydraulic pumps. The prime mover drives the eccentric to rotate, causing the plunger to reciproe, thereby reducing the size of the plunger.

3. The sealing volume will be replaced regularly. When it changes from small to large, a certain degree of vacuum will be formed, so that the oil in the fuel tank will enter the oil chamber through the suction pipe under the action of atmospheric pressure, open the one-way valve, and absorb the oil and it will stop; on the contrary, when the oil volume changes from When the oil pressure changes from large to small, the oil in the cavity will flow into the system by opening the check valve to terminate the oil pressure. In this way, the hydraulic pump converts the mechanical energy input by the prime mover into hydraulic energy. The prime mover drives the eccentric to rotate continuously, and the hydraulic pump continuously absorbs and presses oil.

Packing

Shipping methods

BY EXPRESS, AIR, SEA

About Xinfeng Machinery (XF) parts:

Xinfeng Machinery Parts Company was established in 1998. It is a professional team composed of high-quality technical personnel integrating production, maintenance, sales, and service. It is committed to providing customers with high-quality and efficient services. It is headquartered in Guangzhou, China.

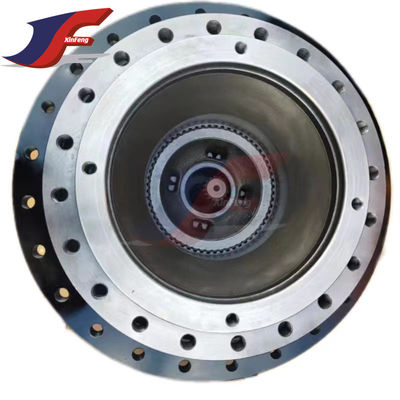

We have been engaged in the excavator industry for 25 years. We sell original used parts, rebuilt parts,original new parts, and OEM new parts for many types.We can provide many types for you to choose from. We can provide a quality-trusted full range of hydraulic pumps, travel motors, final drives, main control valves, swing motors, and engines for KOMATSU, , HITACHI, JOHN DEERE, VOLVO, CASE JCB, KOBELCO, NEW HOLLAND, SUMITOMO, KATO, BOB, DOOSAN, and HYUNDAI.

We provide a customer satisfaction guarantee on all our products. We have invested in providing only the highest-quality replacement parts to our customers. Develop a more broad business space together based on long-term, friendly, mutually beneficial, and win-win business relations.

FAQ

1. How to quickly and accurately buy products what lneeded?

A: Provide the original parts number to us to check.

2. lfI don't know the part number,what shouldI do?

A :Please send us size and pictures of old products.

3. What is the warranty of the products?

A: The warranty is 6/12 Months based on the specific product.

4. How long is your delivery time?

A: The normal delivery time is 3-5 days for stock sproductsafter getting payment. lf not in stock, we will inform you thetime requlred.

5.. What's your erms of packing?

A: Generally,we pack our goods in wooden box.Please letme know if you have any special requirements for packing.

6. Which shipping term you can supply?

A: By sea,air or by express ( DHL,Fedex,TNT,UPSEMS)

7. What is your MOQ?

A: Small order and sample order are acceptable

8. Do you have any After-Sales service?

A: Yes!Our

If you encounter any technical problems with the excavator, you can consult us.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!